High Pressure Water Main Lining

In discussions with Gold Coast City Council, Nuflow's Research and Development team have been working on various methods to reline water mains. A key requirement from council to reline water mains is that the cured liner will hold 1200Kpa of water pressure. Therefore the lab undertook some testing.

The Test

To determine that a Nuflow liner that can hold 1200Kpa for a 24-hour period. In order to provide a true indication if our liner can achieve the above,

the liners in test were cured without any support from the host pipe.

Three types of liner were cured and tested:

- Single Liner

- Double Liner

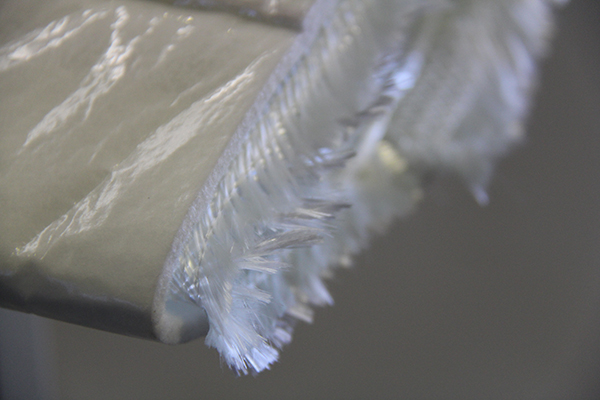

- Double Liner with Single Fibre Glass Scrim

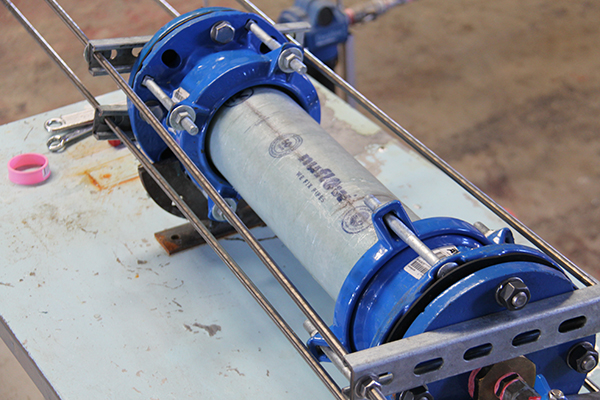

All liners were cured under the same conditions: 65°C hot water cure for 2 hours. All then cut to the same length and put under the same pressure. This provided a fair and accurate testing environment.

The Results

Standard Single Liner

With pressure at 800Kpa the liner held for an observed time of 30 minutes. Pressure was then increased to 1200Kpa. Under this pressure the liner only held for a short two minute period. It did not achieve the required result.

Double Liner

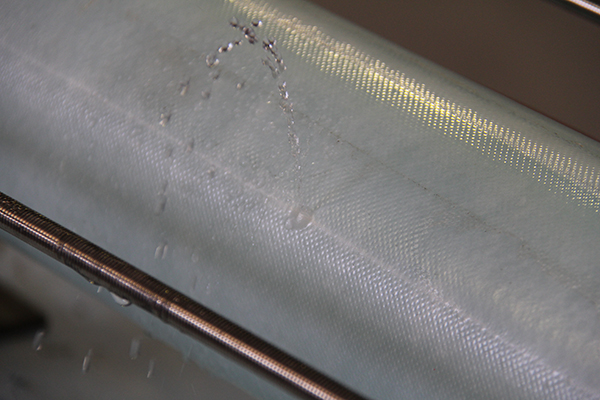

With pressure at 1200Kpa the liner held for an observed 24 hour period. This pressure was then increased to 1800Kpa. Under the increased pressure the liner held for two hours before a pin sized leak formed.

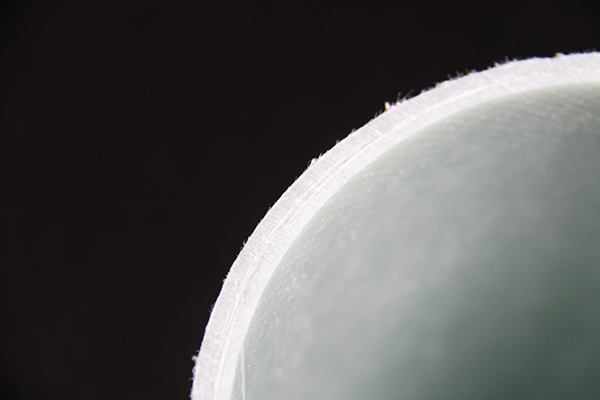

Double Liner with Single Fibre Glass Scrim

This product was constructed with a liner that was 400gsm as opposed to the current 600gsm liner. The product was then manufactured to have the fibre glass sandwiched between the two liners. This resulted in an increased strength with only 40% more thickness to a standard liner.

With pressure at 1800Kpa the liner held for an observed 24 hour period with zero leaks.

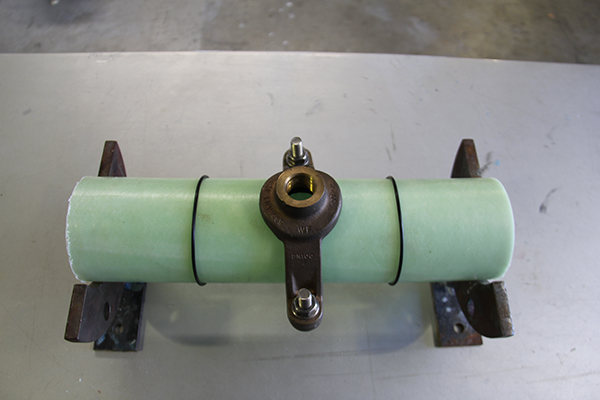

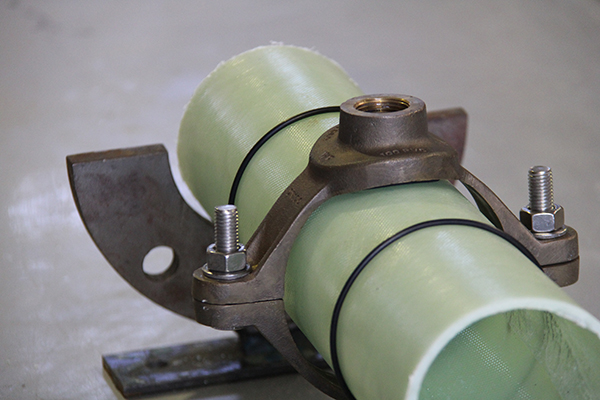

Ferrule Cocks

The challenge was to ensure water did not infiltrate between the liner and the host pipe, finding its way to a crack that was lined over. After some research we found that using particular rubber o-rings on both sides of the entry point resolved the challenge with a result that did not interfere with the reline itself.

A standard rubber o-ring was not suitable as it is hydrophobic (water hating). We sourced a hydrophilic (water loving) o-ring, which absorbs water on contact. As a result it swells and creates an even tighter seal.

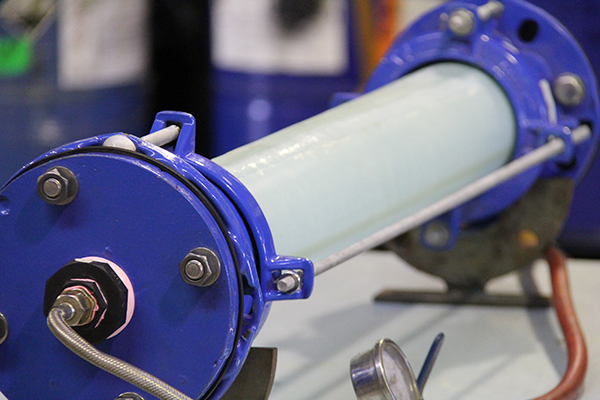

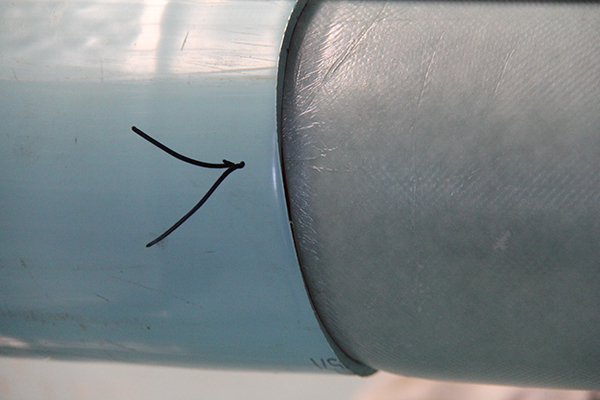

To test if the o-ring itself was enough to seal, we lined a 100mm pressure pipe. The pipe was lined with zero bondage to the host pipe and with the liner protruding out one end. The rubber o-ring was sitting just inside the pipe. We carried out testing on the pipe up to pressures of 1800Kpa. Through all tests the liner and seal stayed in tact proving great success. SummaryFrom the results of our latest Research and Development testing:

- We can supply a composite liner that will hold 1800Kpa unsupported.

- We sourced and tested a rubber ring that can and will hold 1800Kpa without any bondage to the host pipe.

- We can connect directly on to our liner with Gibault joints to install a 'T' in the line.

- We can use a tapping saddle directly onto our liner and create a connection.

- We are developing a tool to re-open house service lines without digging up each connection.